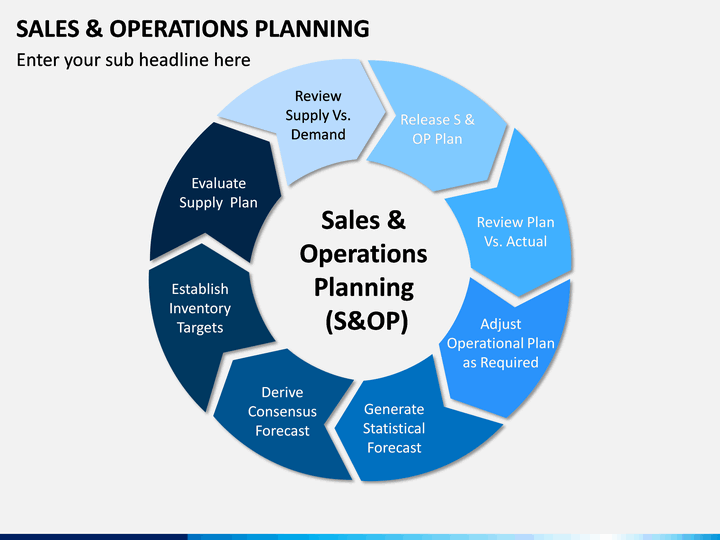

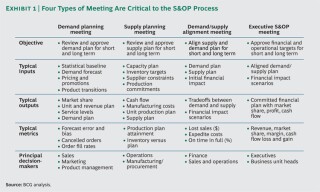

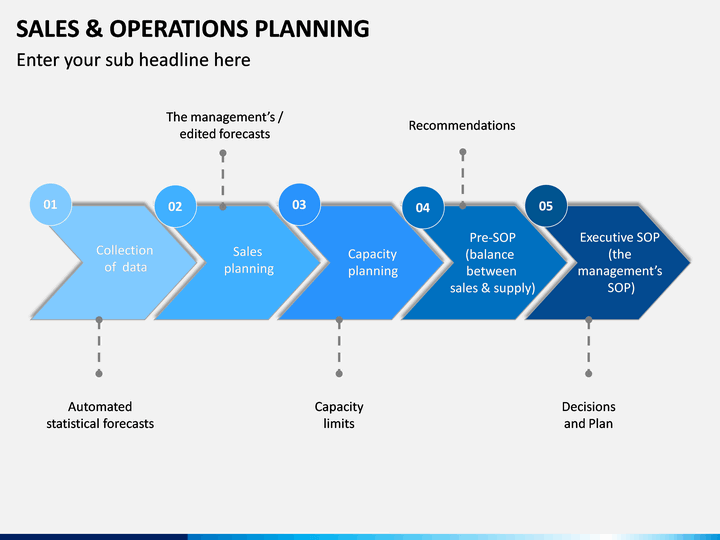

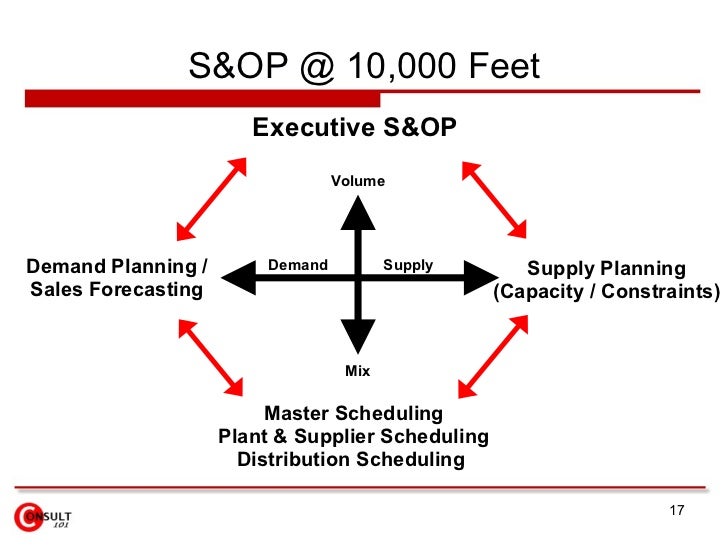

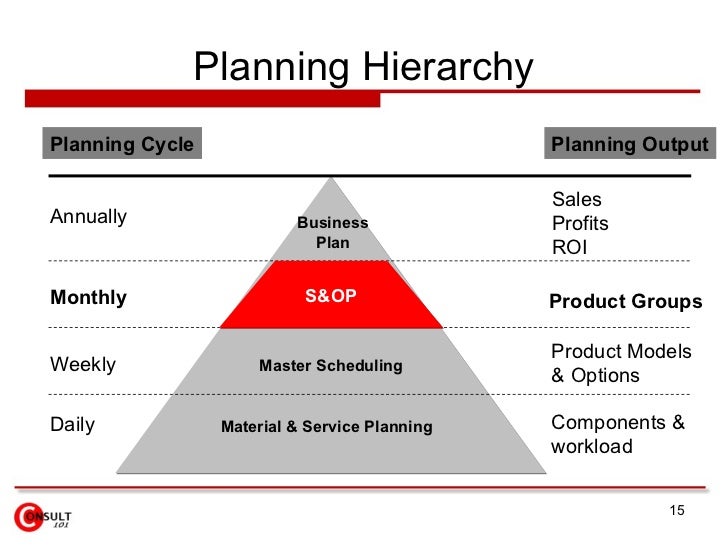

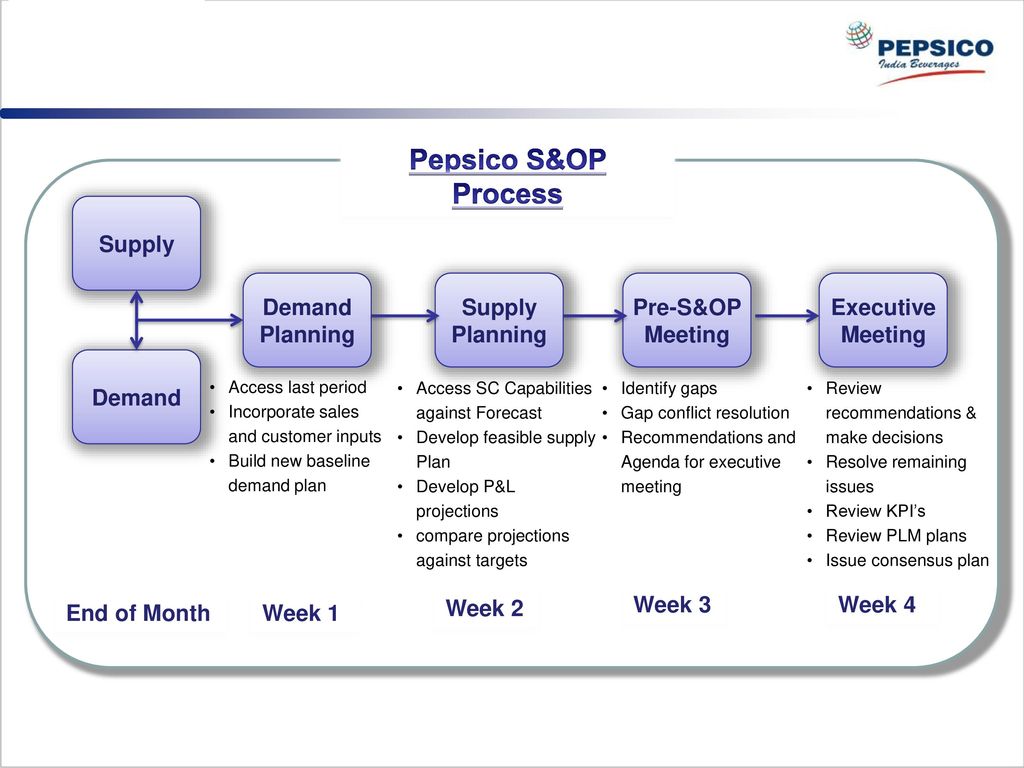

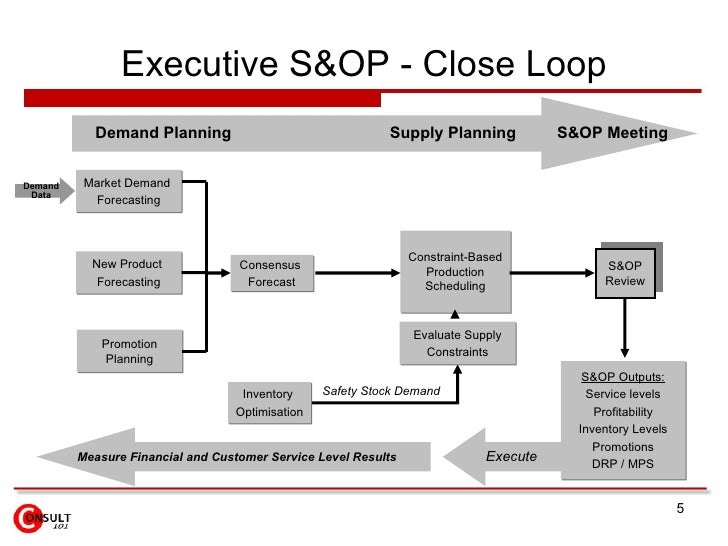

There are two distinct phases to S&OP 1) process design, and 2) process conduct In the design phase, all of the technical workings are engineered, and in the conduct phase S&OP is used as a business management process The following 10 steps describe how to go about these two phases Steps 15 are design and steps 610 are conduct 1 Decide to do it This seems quite obvious,Sales and operations planning (S&OP) is an integrated business management process through which the executive/leadership team continually achieves focus, alignment and synchronization among all functions of the organizationThe S&OP process includes an updated forecast that leads to a sales plan, production plan, inventory plan, customer lead time (backlog) plan, new productTime Horizons The S&OP planning horizon is typically in the range of 12 – 24 months, but this can differ depending on specific circumstances

S Op Implementation Roadmap

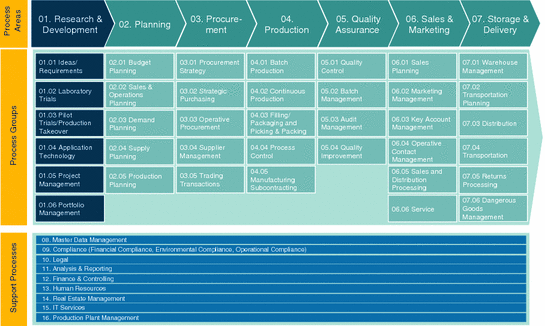

Sop process map

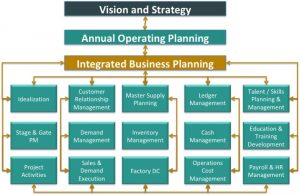

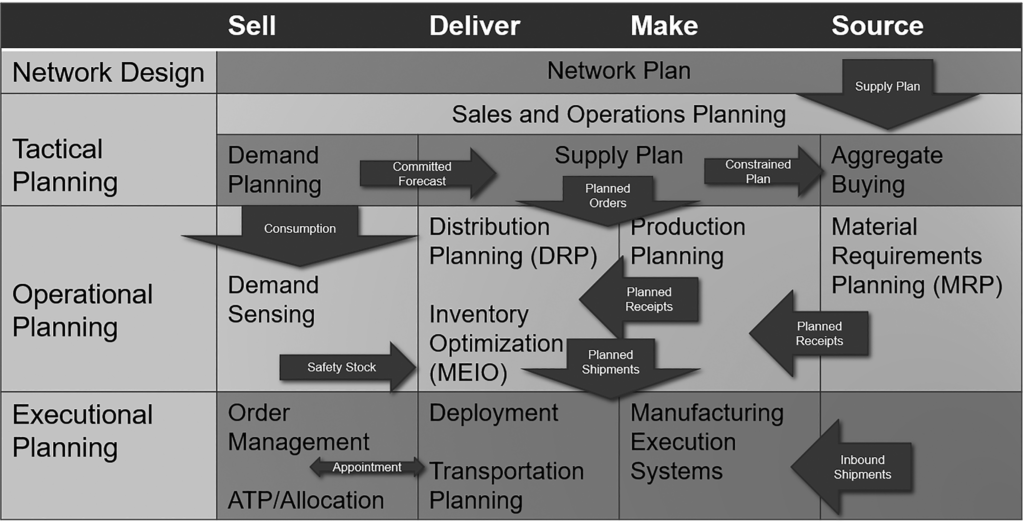

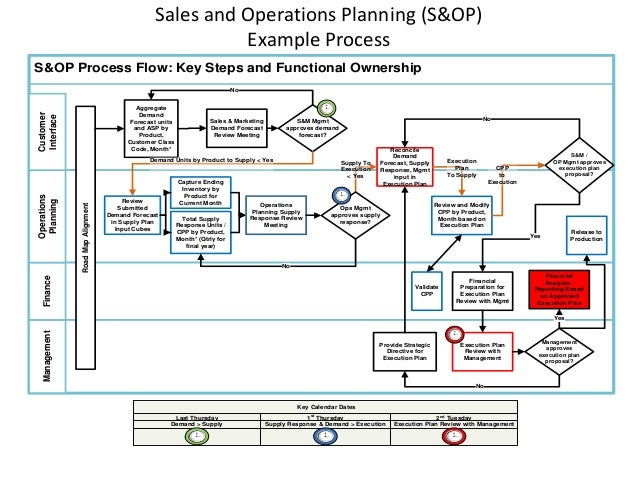

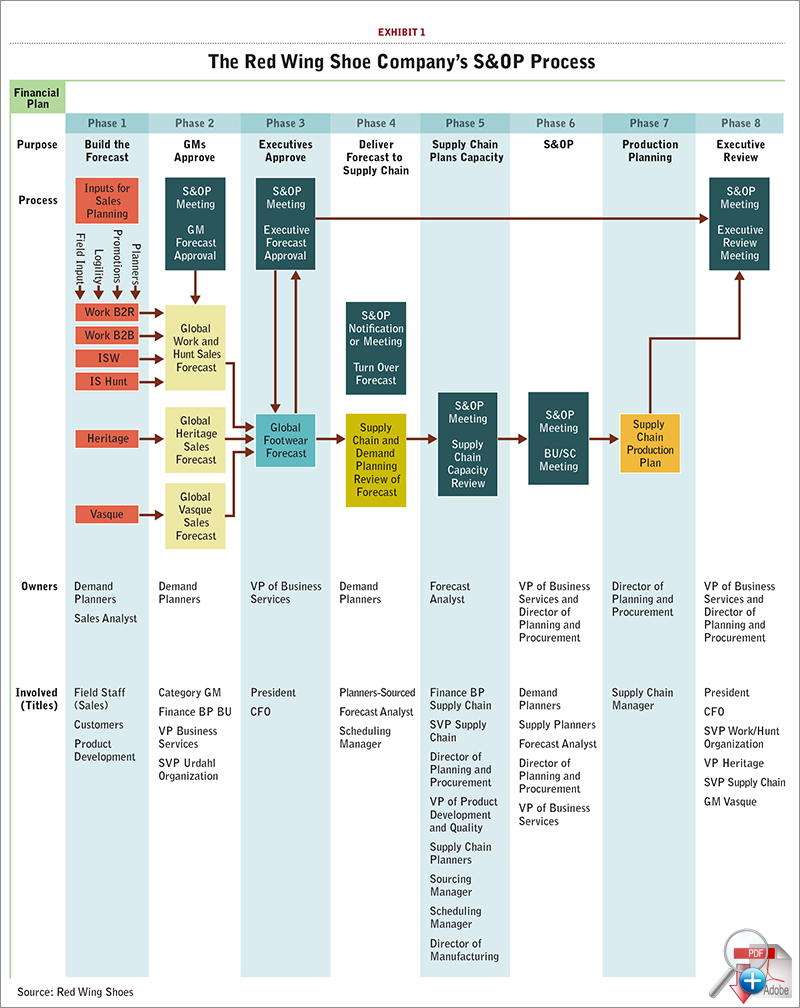

Sop process map-No Yes Perform root cause analysis Map and implement the "tobe" process Collect Data Is the process stable?The S&OP process should be separated from operational planning without losing the link, though The S&OP planning process should always be built on a realistic foundation, as the base line determines the trustworthiness of the S&OP plan That is why the operational plan should integrate towards IBP for S&OP (preferably via HANA Cloud Integration, HCI) HCI allows you to integrate

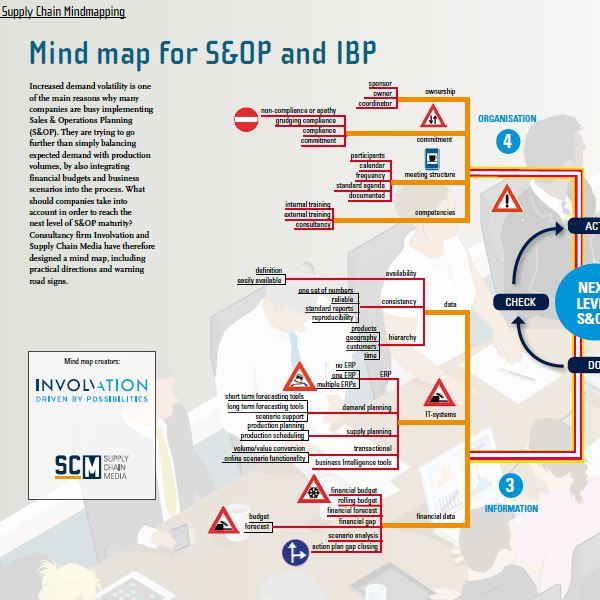

Mindmap For S Op And Ibp Supply Chain Movement

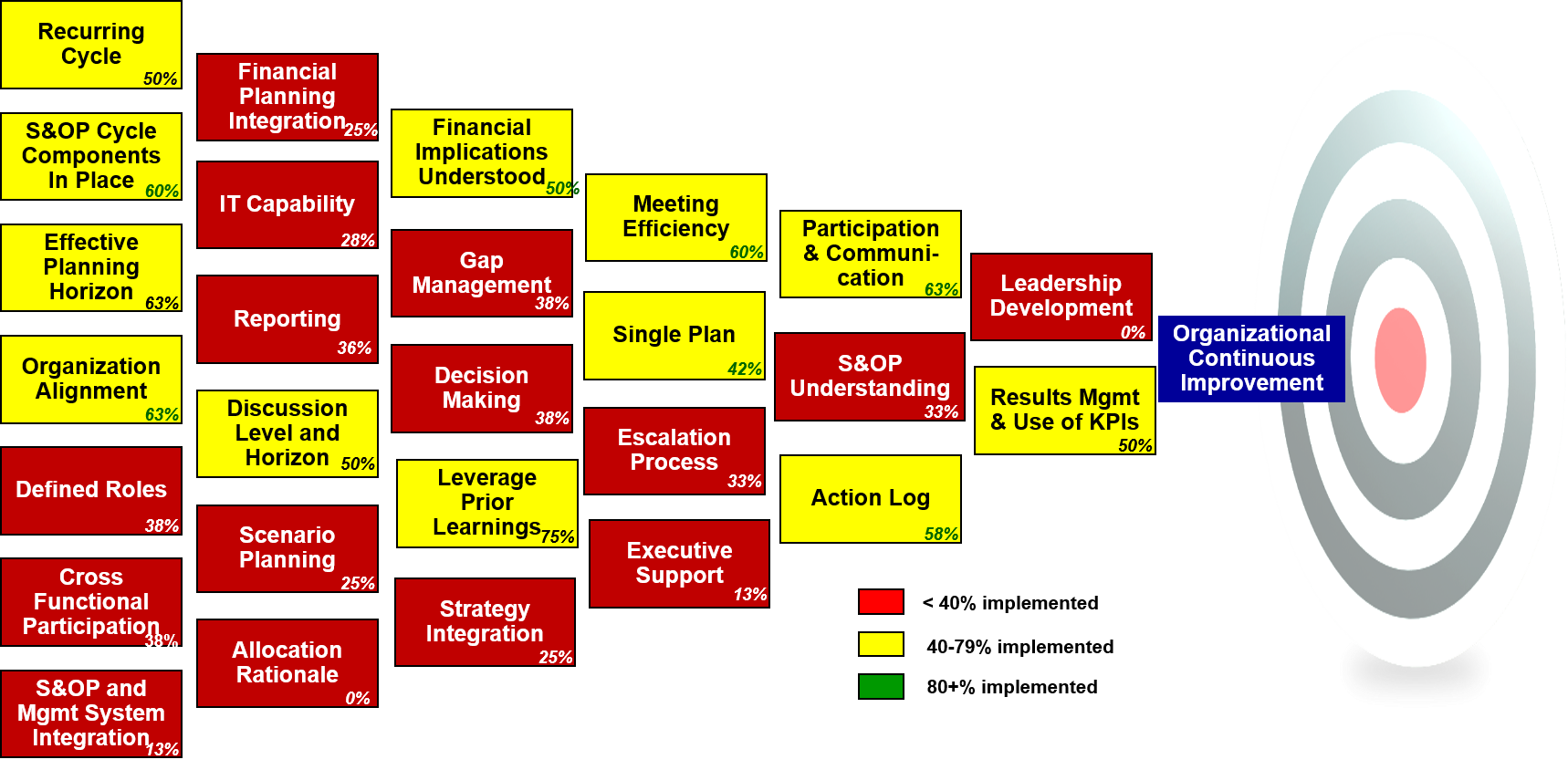

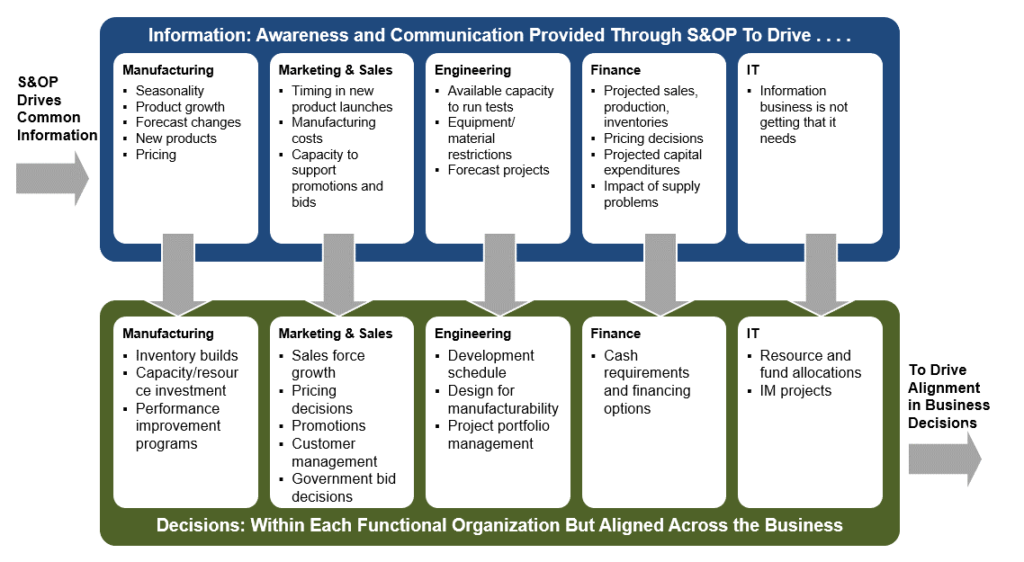

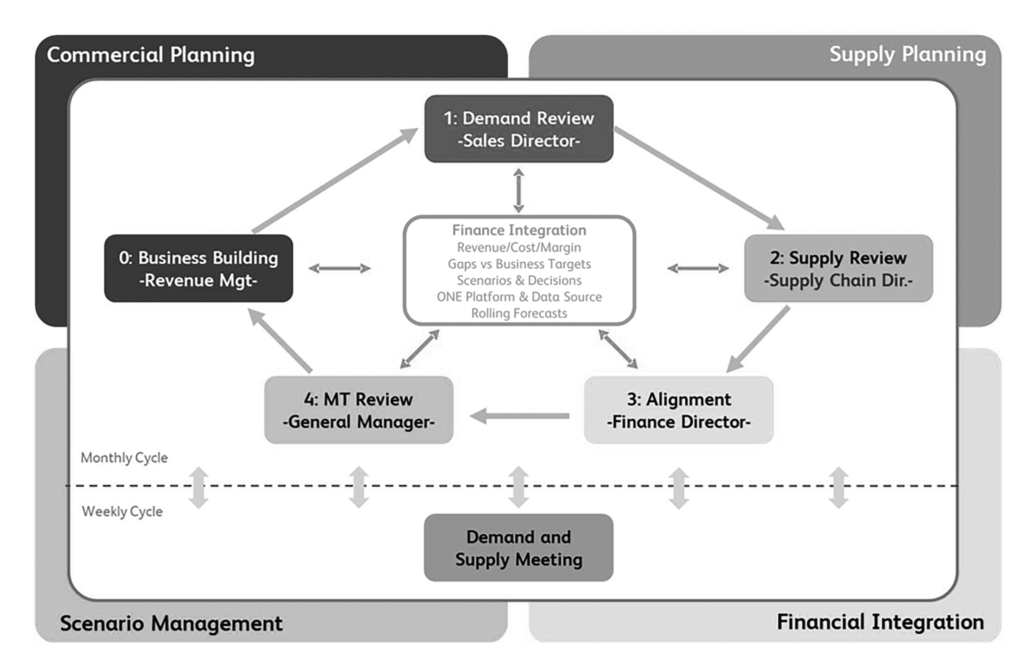

Map to Profit Center Leadership Drive Alignment to Business Goals The starting place is to build an organizational map by profit center For the greatest success, the S&OP process should report to a profit center manager The number of S&OP processes align to the profit center mapping (The average company has five to six processes, and the greatest progress happens when there isNo Yes Is it capable?S&OP is an integral process, which means the active involvement of Finance, Sales, Product Management, Production, Purchasing, etc To what extent does everyone within the company regard the S&OP process as the platform for looking ahead and making decisions?

What Is Sales and Operations Planning (S&OP)?Reporting structure Each S&OP process is chaired by its P&L responsible manager;According to IBF, S&OP is a process that coordinates different areas of the business to meet customer demand with the appropriate level of supply When establishing your process, it is important to consider who will be responsible for each step of the process You will also want to set expectations for handoffs, meetings, and how you will communicate changes Effective S&OP

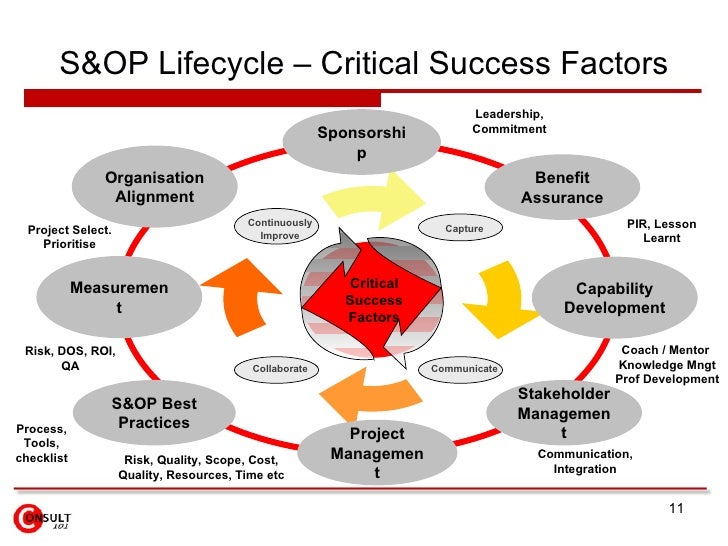

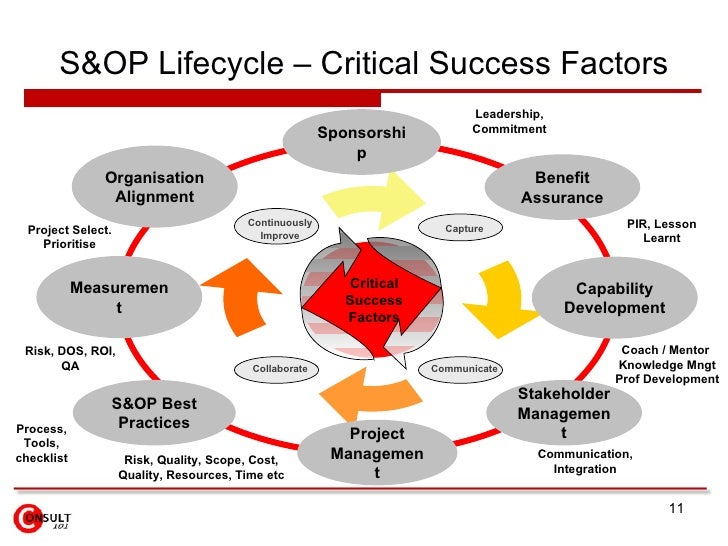

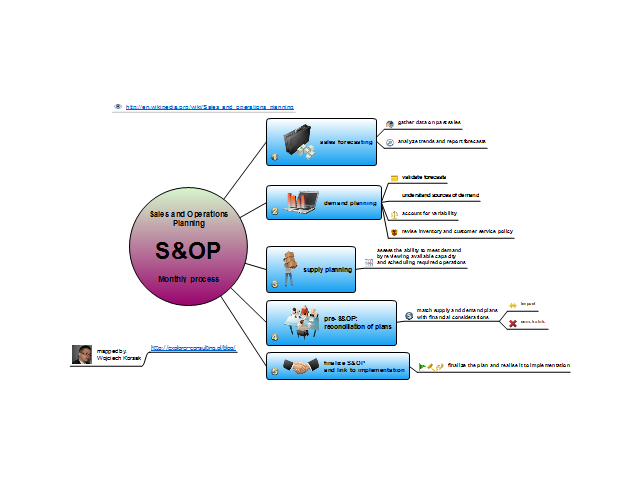

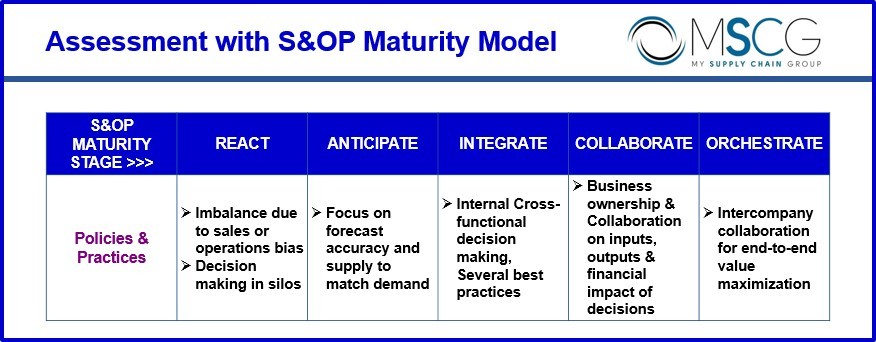

With a trusted S&OP process and leadership commitment lead to effective S&OP Because S&OP is a continuous process and reliant on new information, it improves from actual practice even at the risk of temporarily unfavorable outcomes TIP Identify optimal planning horizons by department and consider each department's planning needs In general, the more mature the S&OP practice, theSales and operations planning (S&OP) is a popular process that aligns a company's diverse functions while balancing supply and demand S&OP gives executives a comprehensive overview of the business so they can grasp where it stands (in all its complexity) This allows them to continuously match highlevel strategy with daytoday operational tactics in all departments"walk the talk" Achieving process compliance Identifying S&OP Champion or expert to lead implementation Clear definition and acceptance of roles and responsibilities, including defining specific objectives in employee appraisals Establishing S&OP meetings as the business priority Adapting the process to the

S Op Made Practical The European Business Review

2

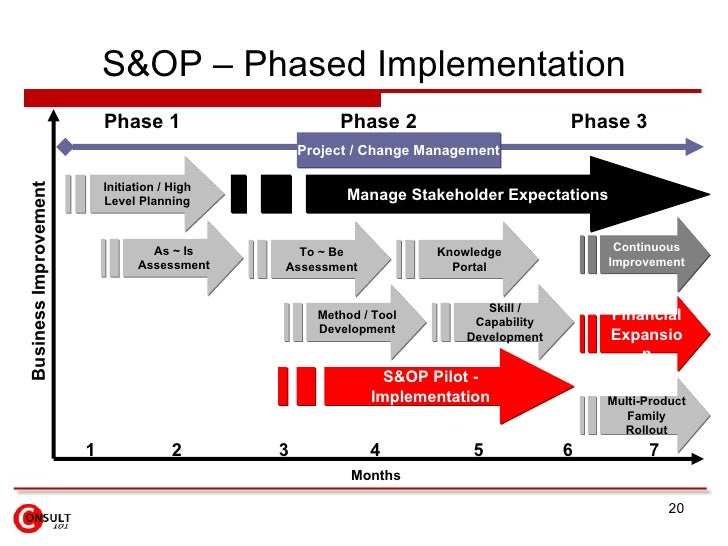

Estimated Reading Time 4 minsS&OP process needs a strong foundation and requires the following to be established Establish, in writing, senior management support, clear organizational expectations, longrunning commitment, and positional empowerment Create and deliver value through optimal alignment of strategic goals and tactical execution of those goals that accounts for organizational strengths and pain pointsImplementing or eimplementing a World Class SI&OP process starts by following a proven roadmap using a "Phased Approach" to achieve major mile markers Don't expect too much, too fast — start with a pilot area and build from there Identify the key wants/needs of your major players (Finance, Sales, Operations) and begin modeling a straw man process You may need to

S Op Made Good The Importance Of Investing In People Reuters Events Supply Chain Logistics Business Intelligence

The S Op And The 3 Different Levels Of General Planning Based On Apics Download Scientific Diagram

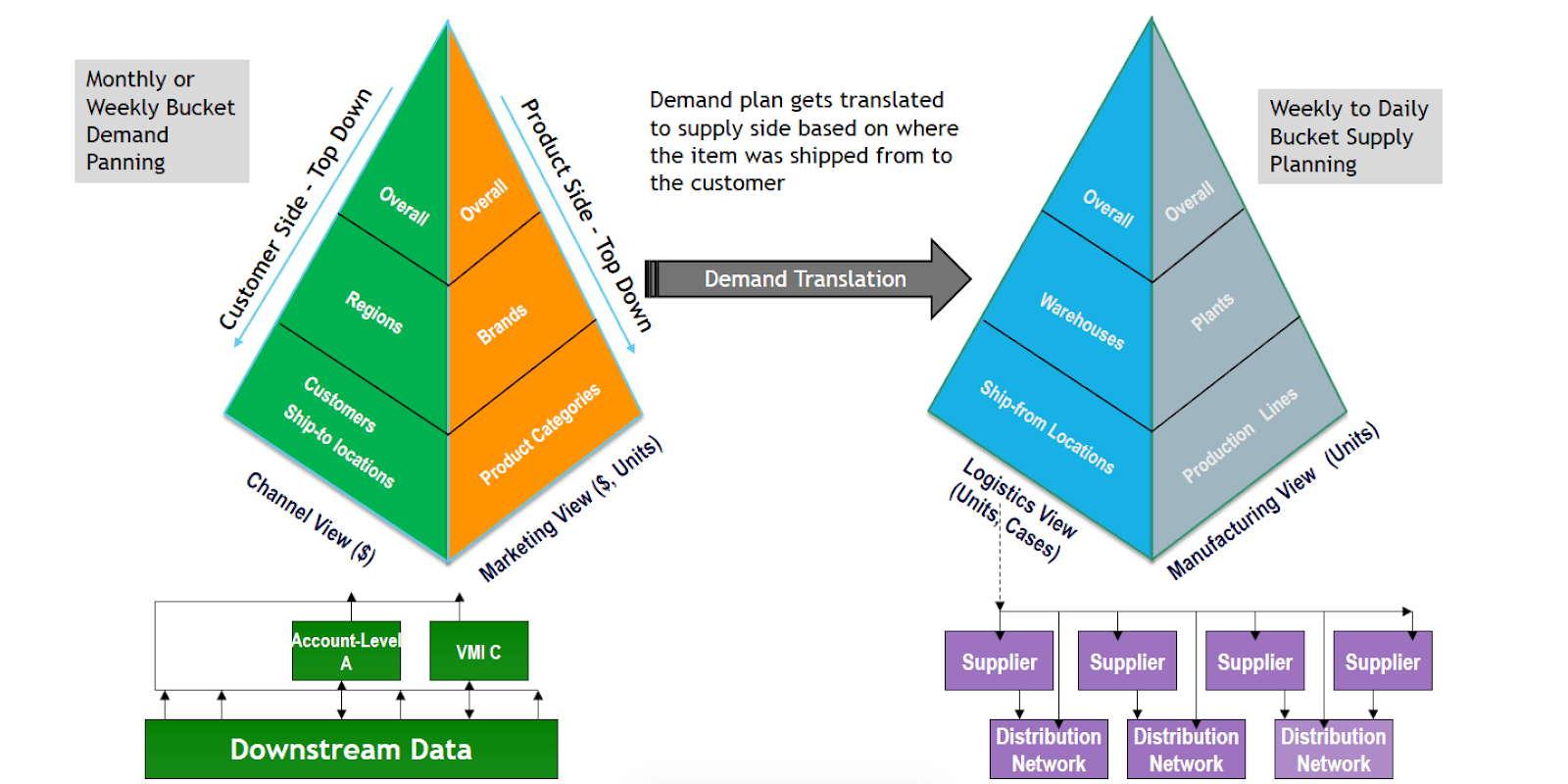

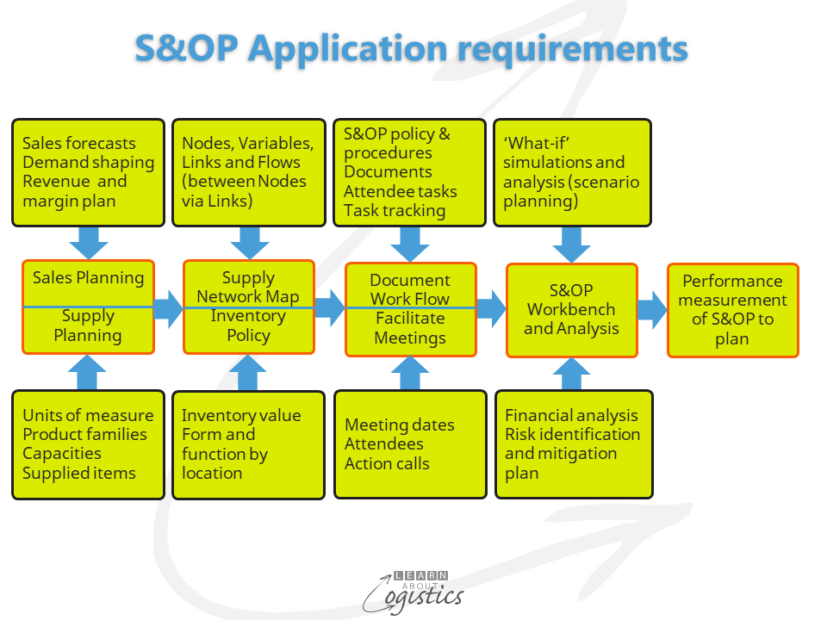

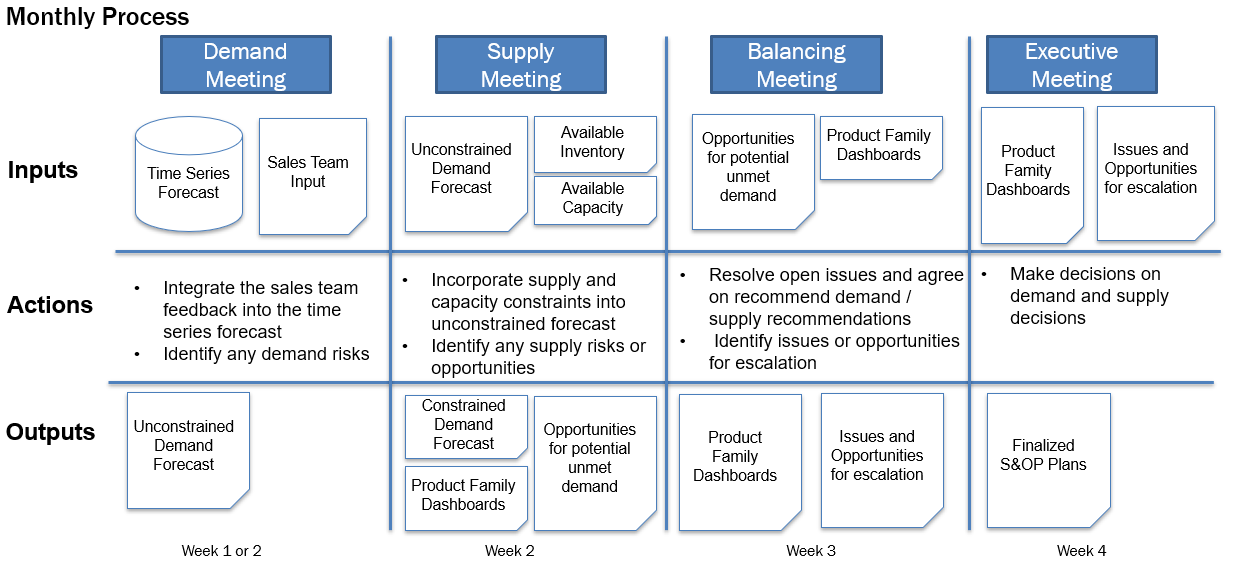

S&OP Process Mapping Select the process Get the right people together Establish process boundaries List steps, activities and decisions Map the "asis" process Simplify the process Collect Data Is the process stable?Supply Network flows Mapping the nodes and links of the Network Illustrate the interrelationships of SBUs/divisions within the enterprise;Figure 1 The S&OP Process S&OP is a process that coordinates different areas of the business to meet customer demand with the appropriate level of supply Implementation of S&OP should be undertaken in phases Most businesses start with a pilot program in one business unit in one country, for example S&OP has been around for over years now, and many firms

Enchange Supply Chain Consultancy Strategy Map

Mindmap For S Op And Ibp Supply Chain Movement

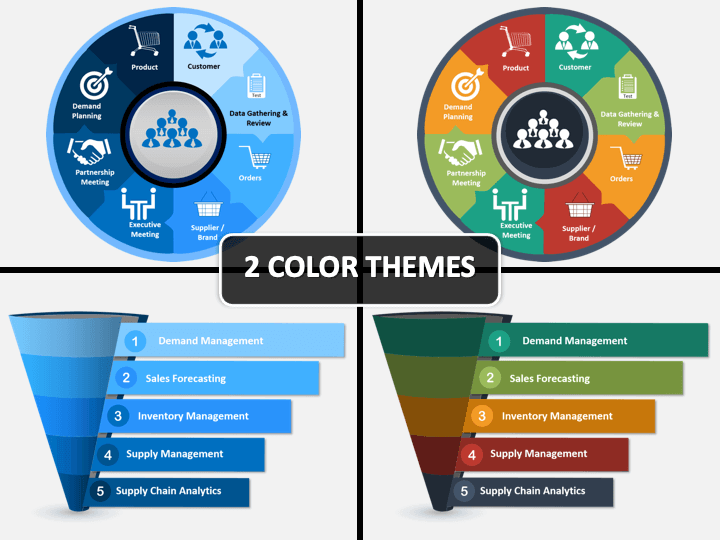

Sales and operations planning is an aspect of supply chain planning whose goal is the creation of a unified, consensusbased business plan It draws input from an organization's key functional areas, including sales, marketing, manufacturing, distribution, and financeThe S&OP process includes forecasting, demand and supply planning, and executive review The goal is to coordinate sales and operations planning across business functions so they're all on the same page The exact steps can vary depending on the company, its products, and its industry 1 Forecasting At this stage of the S&OP process, data is gathered about prior salesS&OP fosters clear and unambiguous communication and this strengthens teamwork

Sales And Operations Planning Powerpoint Template Sketchbubble

1

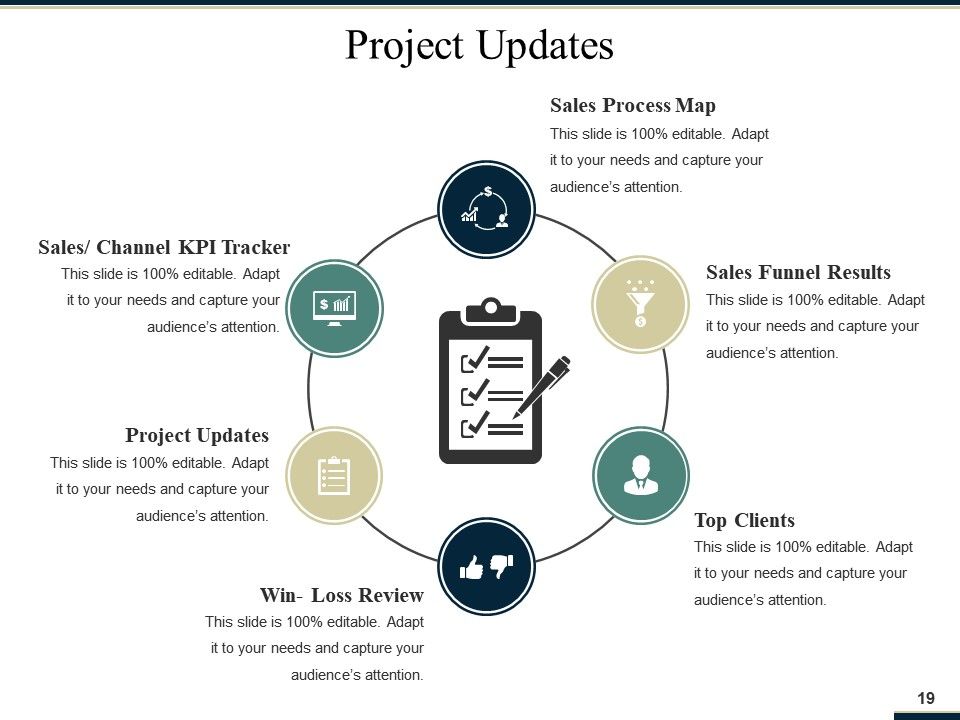

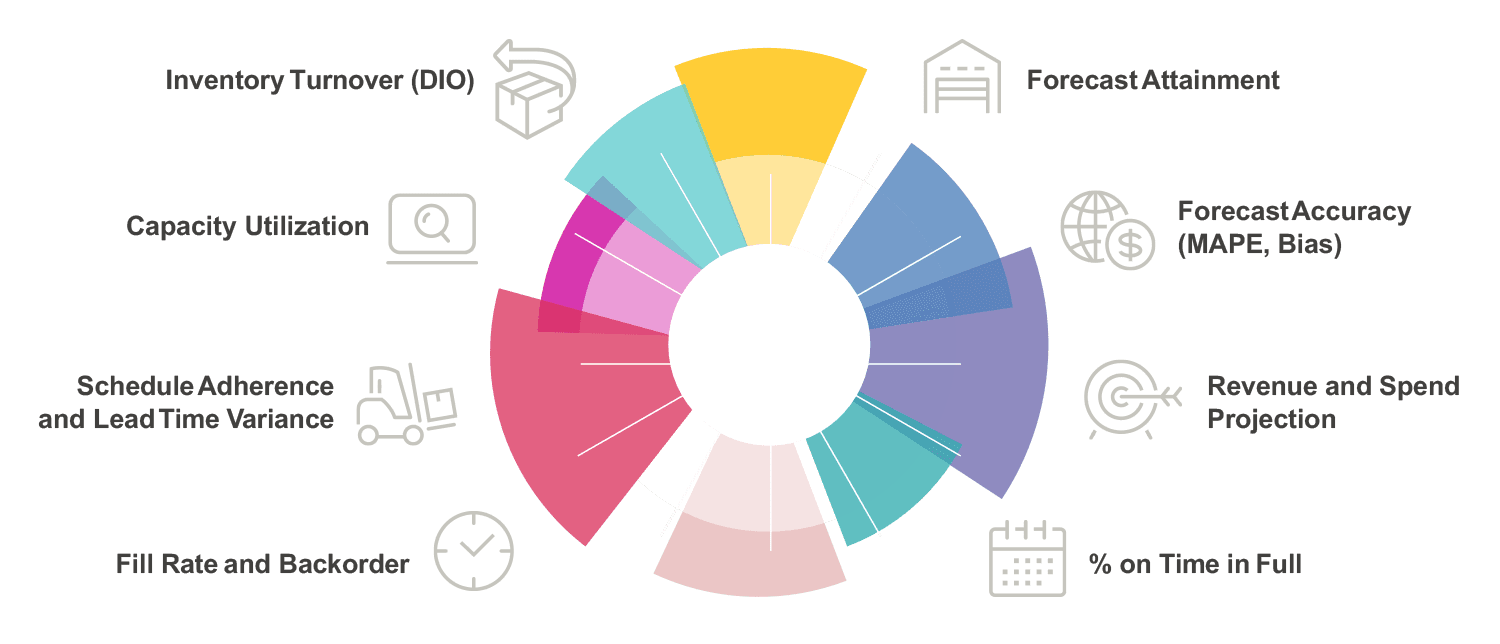

The S&OP process leader does the leg work to coordinate the various parties in order to gain support and foster the development and recommended paths to solving issues coming into this meeting This means prepresenting to key executive team members, getting their informal opinions, and defining the next level down team's recommendation that has dollar implicationsA common struggle for any endtoend process management is identifying the right measures that encapsulate the value of the process This interactive article contains key performance indicators (KPIs) that allow organizations to focus all participants in the endtoend sales and operations planning (S&OP) process on a shared goal that aligns with theS&OP Challenges Challenges Senior leadership support &

What Is One Plan S Op Arkieva

S Op Five Steps To Get Started Supply Chain Shaman

After defining the participants and their responsibilities within the S&OP process it is necessary to communicate this to all stakeholders and deliver training (if required) to ensure each individual is capable of fulfilling their role This is a simple thing that goes a long way to getting S&OP off the ground and ensuring it is sustainable and manageable with the right participants,

Self Assessment L Nexview Consulting S Op Consulting

Mindmap Sales Operations Planning S Op Supply Chain Movement

S Op Implementation Roadmap

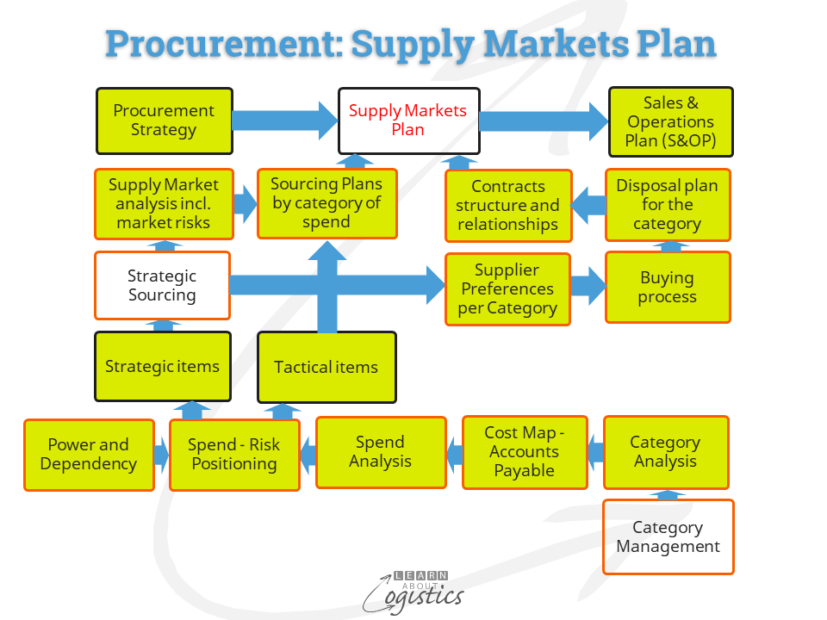

Supply Markets Plan Is A Supply Chain Input To The S Op Learn About Logistics

Sales And Operations Planning Powerpoint Presentation Slides Presentation Powerpoint Templates Ppt Slide Templates Presentation Slides Design Idea

What Is S Op How S Op Works Demand Planning Com

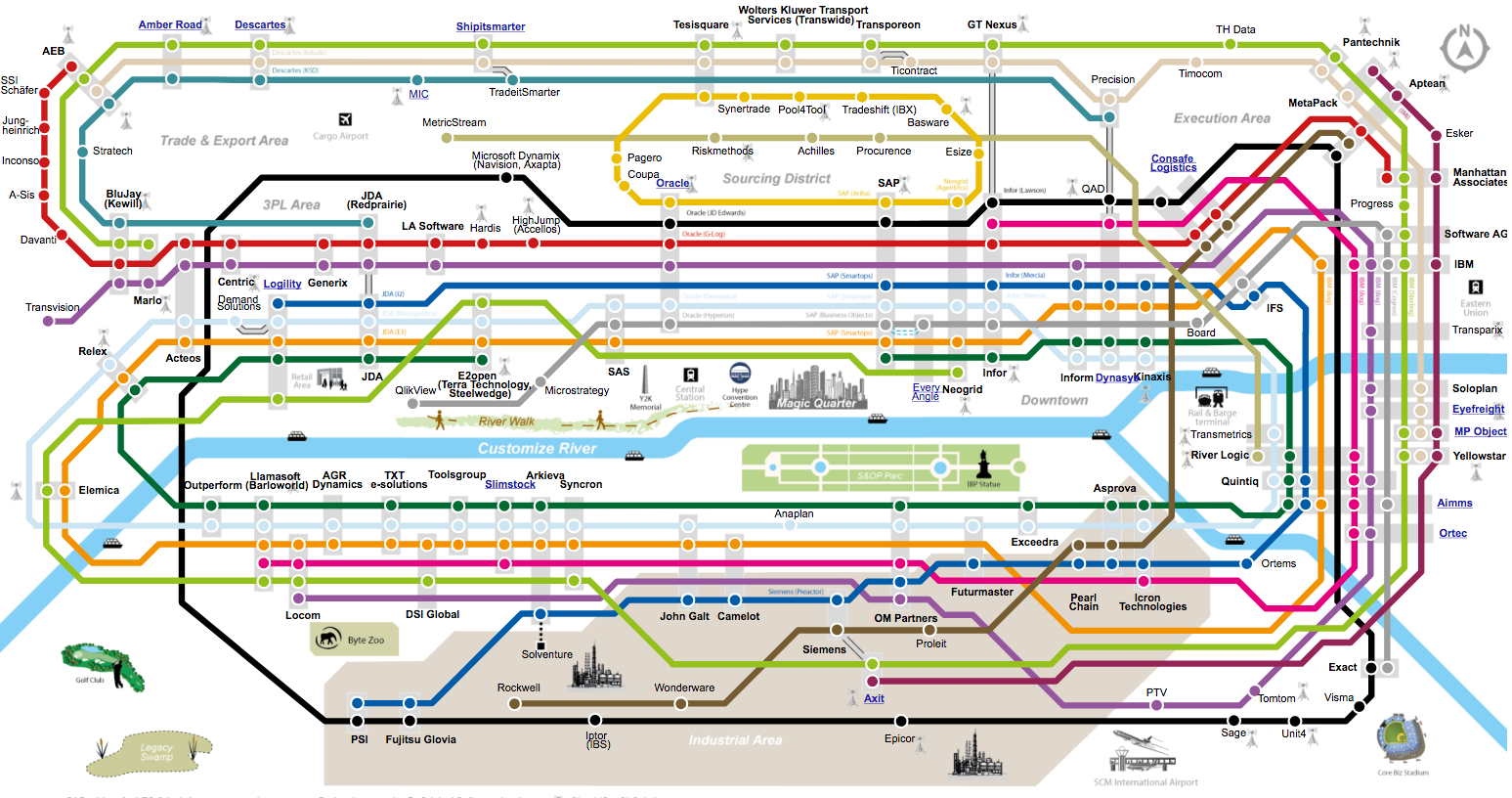

Aimms Featured In It Subway Map Of European Supply Chain Software Providers Aimms

Sales And Operations Planning

1

Sales And Operations Planning Powerpoint Presentation Slides Presentation Powerpoint Templates Ppt Slide Templates Presentation Slides Design Idea

S Op A Vision For The Future The Expert Interview Series 1 Supply Chain Trend

The S Op Framework Source Thome Et Al 12 Download Scientific Diagram

Mindmap For S Op And Ibp Supply Chain Movement

Sales And Operations Planning Explorescm

1

Oracle Demantra Sales And Operations Planning User Guide

Sales Operations Planning Presentation 60 Slide Powerpoint Flevy

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

Sales And Operations Planning Powerpoint Template Sketchbubble

S Op Heuristics Flow Chart Download Scientific Diagram

A Rudder For Course Correction July 1 09 Cscmp S Supply Chain Quarterly

Mindmap For Sales Operations Planning 2 0 Supply Chain Movement

Getting To Grips With Sales And Operational Planning Bloor Research

1

Sap Sales And Operations Planning Software Product Xsop Pdf Free Download

S Op Implementation Roadmap

The Client Journey Leadership Through Integration Dm Integration

Blogs

Framework For Measuring Performance Of The Sales And Operations Planning Process Emerald Insight

2

Supply Planning Processes Options Analytics Oh My Plex Demandcaster

Sales And Operations Planning S Op Monthly Process Conceptdraw Biggerplate

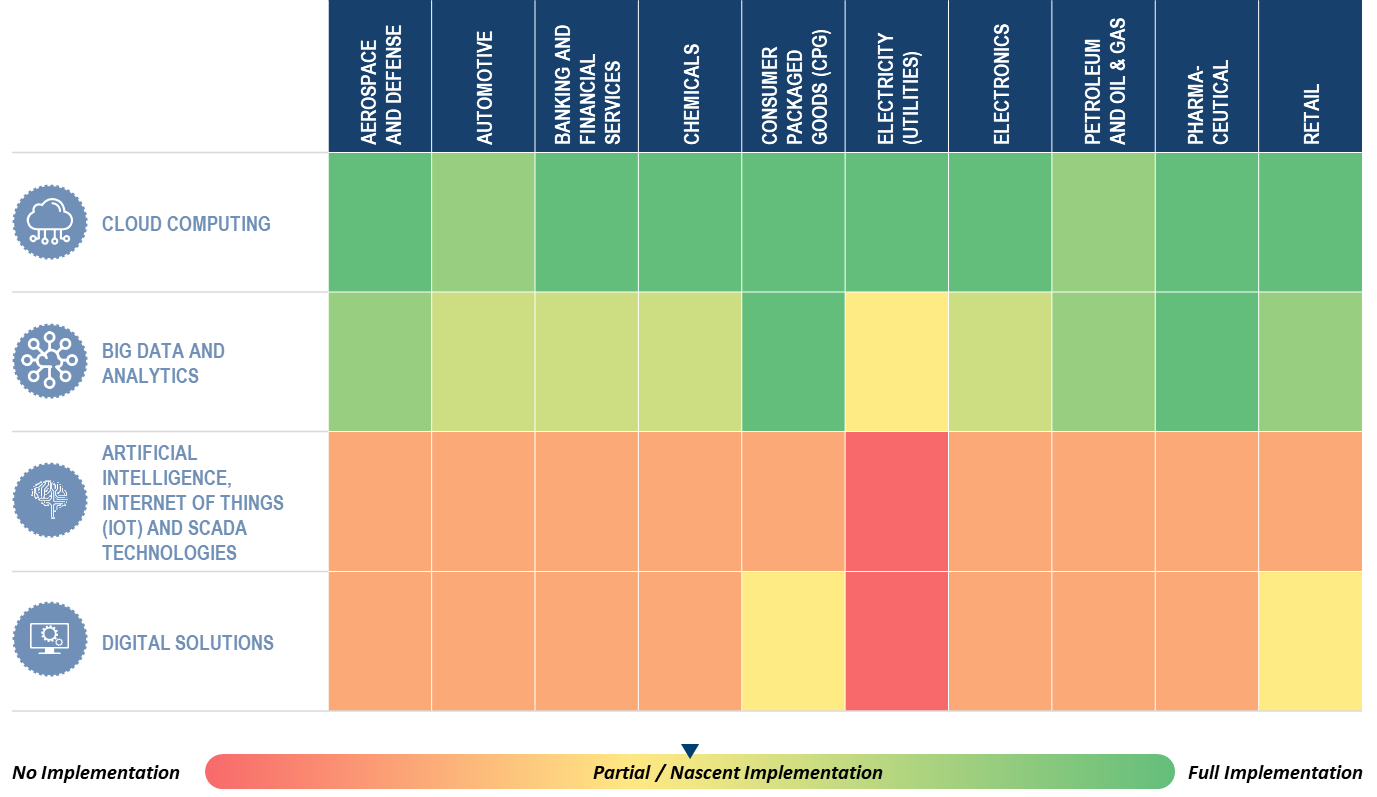

Enterra Insights Nine Technologies Transforming The Supply Chain Part 2

S Op Process

The 5 Most Common Sales Operations Planning Mistakes And How To Avoid Them Supply Chain 24 7

2

S Op Five Steps To Get Started Supply Chain Shaman

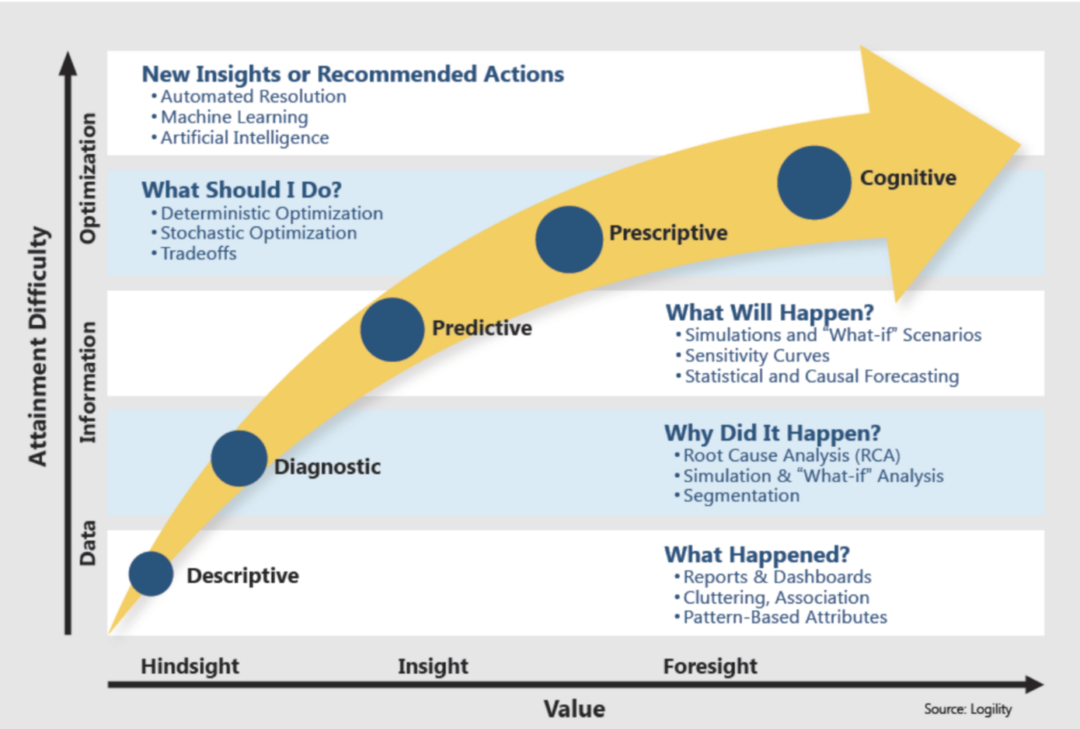

How These 6 Technologies Can Advance Your Sales Operations Planning Apqc

Applications Requirements That Assist S Op Decisions Learn About Logistics

Achieve Excellence In Sales And Operations Planning Sapinsider

23 S Op Ideas Sales And Operations Planning Supply Chain How To Plan

Sales And Operations Planning S Op 101 Smartsheet

Sales And Operations Planning Powerpoint Template Sketchbubble

Sales Operations Planning Consulting Supply Velocity

Food Production Processing Operations Transformations All Revolve Around Process First A Case Study In Modern Process Mapping

Five Ways To Upgrade Your Business Planning Process With Advanced Analytics 18 07 24 Supplychainbrain

What Is S Op How S Op Works Demand Planning Com

Is S Op Excellence Slip Slidin Away Supply Chain Shaman

Is S Op Excellence Slip Slidin Away Supply Chain Shaman

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

The Effect Of Sales And Operations Planning S Op On Supply Chain S Total Performance A Case Study In An Iranian Dairy Company Sciencedirect

What Is A Process Map Process Flow Chart Bizmanualz Process Flow Chart Process Map Order To Cash

What Is S Op How S Op Works Demand Planning Com

S Op Sales And Operations Planning And Sco

A Comprehensive Overview Of Sales And Operations Planning S Op

A Comprehensive Overview Of Sales And Operations Planning S Op

Achieve Excellence In Sales And Operations Planning Sapinsider

S Op Process

S Op Process Challenges In Beverage Industry Ppt Video Online Download

Mindmap For Sales Operations Planning 2 0 Supply Chain Movement

S Op Sales And Operations Planning And Sco

Generalized Scor Implementation

Sales And Operations Planning In Manufacturing Manage Collaboration Across The Entire Organization Tompkins Solutions

Sales Operations Planning S Op And Sales Operations Execution S Oe Engineering Usa

Solution Framework Of S Op In The Supply Chain Download Scientific Diagram

Sales Operations Planning Engagement Model Tvo Maine Pointe

Framework For Measuring Performance Of The Sales And Operations Planning Process Emerald Insight

The Effect Of Sales And Operations Planning S Op On Supply Chain S Total Performance A Case Study In An Iranian Dairy Company Sciencedirect

S Op Implementation Roadmap

S Op Sales And Operations Planning And Sco

The Fully Integrated S Op Of A Multi Site System In Supply Chain Download Scientific Diagram

Supply Chain Process Map How To Start Building It

Utilizing A Roadmap For A Successful S Op Implementation Avata

The Lost Link To Make Strategy Work Sales Operations Planning S Op Strategok By Javier Go Sales And Operations Planning Business Architecture Strategies

Mapping Business Processes In The Process Industry Selected Examples Springerlink

Mindmap For S Op And Ibp Supply Chain Movement

S Op Implementation Roadmap

2

S Op 360

S Op Implementation Roadmap

Monthly S Op Process Sales And Operations Planning Wikipedia Sales And Operations Planning Best Apps For Teachers Apps For Teachers

3 Primary Components Of Sales Operations Planning People Process And Technology Supply Chain 24 7

Sales And Operations Planning Powerpoint Presentation Slides Presentation Powerpoint Templates Ppt Slide Templates Presentation Slides Design Idea

From Chaos To Control July 1 08 Cscmp S Supply Chain Quarterly

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Road Map Of Integrated Business Planning For Supply Chain Part Ii The 5 Ps Of S Op Maturity My Supply Chain Group

Sales Operations Planning Omnics

S Op Heuristics Flow Chart Download Scientific Diagram

S Op Five Steps To Get Started Supply Chain Shaman

Achieve Excellence In Sales And Operations Planning Sapinsider

Integrating The S Op Process The Planning Blog Sales And Operations Planning Master Schedule Process

Sales Operations Planning Omnics

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

The Fully Integrated S Op In Supply Chain Planning Context Download Scientific Diagram

0 件のコメント:

コメントを投稿